CORMETECH, Inc., the world’s leading SCR catalyst manufacturer, has brought its years of experience in SCR catalyst development to offer an innovative high dust SCR solution that surpasses currently available catalyst technologies. The unique CORMETECH DustBuster™ SCR catalyst consists of optimized channel geometries that significantly improve the flow of ash-laden flue gas through the catalyst cells while still delivering enhanced DeNOx and SO2 performance, product reliability, and catalyst life cycle benefits of extruded platforms. Additionally, the uniform rectangular, large hydraulic diameter openings deliver optimized aspect ratios to prevent dust build up and catalyst pluggage inside the SCR reactor.

CORMETECH, Inc., the world’s leading SCR catalyst manufacturer, has brought its years of experience in SCR catalyst development to offer an innovative high dust SCR solution that surpasses currently available catalyst technologies. The unique CORMETECH DustBuster™ SCR catalyst consists of optimized channel geometries that significantly improve the flow of ash-laden flue gas through the catalyst cells while still delivering enhanced DeNOx and SO2 performance, product reliability, and catalyst life cycle benefits of extruded platforms. Additionally, the uniform rectangular, large hydraulic diameter openings deliver optimized aspect ratios to prevent dust build up and catalyst pluggage inside the SCR reactor.

Eliminating ash accumulation during coal power generation, especially in “high dust” environments in the flue gas, can lead to reduced plugging and erosion of the SCR catalyst and improve overall reactor performance. Coal-fired power plants globally utilize a range of opportunity fuels to produce the lowest cost power. These coals have varying levels of ash, which can be detrimental to a power plant’s downstream air pollution control equipment, specifically SCR catalysts used to reduce NOx emissions.

- Ultra-high plugging and erosion resistant catalyst

- Larger hydraulic pitch delivers significantly higher surface area per open area vs. plate

- Rectangular cells with low aspect ratio improve ash flow

- Extremely low SO2 oxidation capability

- Uniform cell geometry with 100% catalyst material structure

- No plate corrosion and catalyst delamination

- Extends catalyst lifecycle / environmentally friendly – 100% regenerable or recyclable

- Designed for optimal long-term regeneration – eliminates iron that will increase SO2 oxidation

- Made in the USA

- The effects of fly ash on SCR catalyst and systems

- Effective high dust coal application design strategies – How to bust the dust?

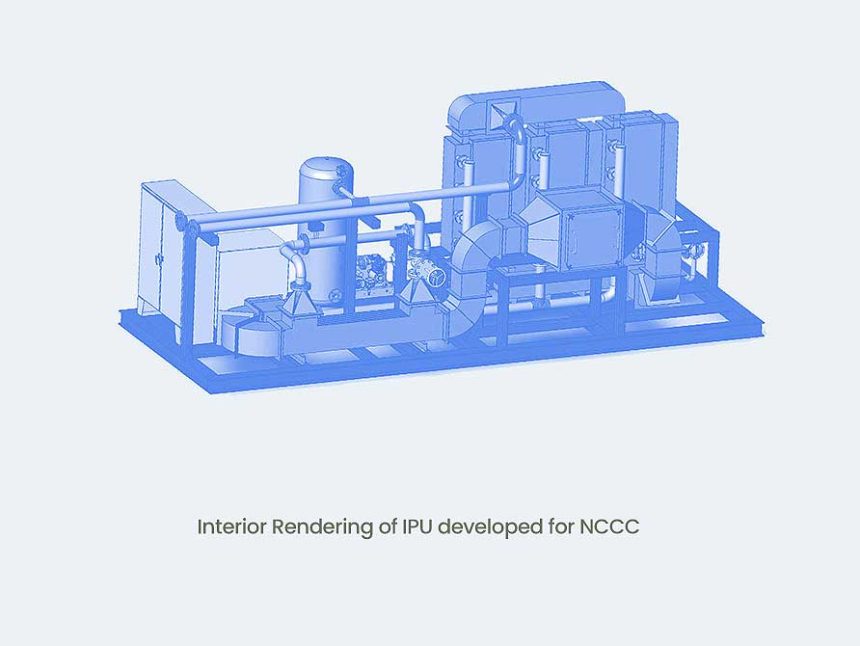

- SCR operational strategies in high dust environments including Hybrid and PowerCore configurations

- Experimental and Commercial Application Field data case study results evaluating DustBuster™ and Plate catalyst pluggage and erosion performance

- Benefits of DustBuster™ regeneration and TiO2 recycling

This webinar will help you make informed decisions about flexible strategies for maintaining an effective and efficient SCR catalyst under high dust applications by extending catalyst lifecycle and reducing overall maintenance & compliance costs.

Attendees are encouraged to ask questions which will be covered during the Q&A session of the webinar. Register today to secure your spot in this free webinar! Presenters Scott Daugherty | Senior Vice President of Global Business Development | CORMETECH Inc.

Mr. Daugherty has been with CORMETECH for 15 years and has responsibility for worldwide sales, marketing and business development of the SCR catalyst and services businesses. Scott manages coal, natural gas and specialty catalyst sales teams, 5 CORMETECH licensees in China and a worldwide distributor and rep organization. Scott is accountable for CORMETECH’s global sales growth strategy.